-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- High-Speed and Ultracentrifugation Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

A guide to impeller selection

Lab Academy

- Bioprocessing

- Cell Culture

- Efficiency

- Bioprocess

- Essay

When growing microorganisms or mammalian cells in a stirred-tank bioreactor, it is critical to pick the impeller type that best suits the process. Selecting the wrong impeller could make chop suey of your filamentous fungi.

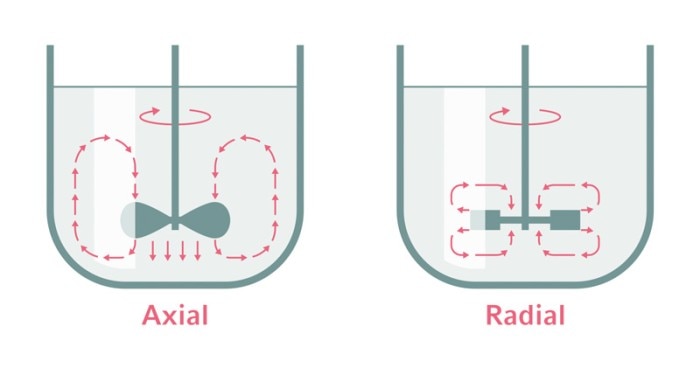

How blade orientation affects mixing

All stirred-tank bioreactors are designed to homogenously mix cells, nutrients, and gases. The impeller evenly distributes oxygen and substrates to the cells for healthy growth. It keeps them from settling to the bottom of the vessel and helps maintain a stable, even temperature. Depending on the impeller you choose, mixing will be achieved by radial or axial flow – or a combination of both.Read more

Read less

Rushton and Rushton-type impellers: Ideal for fermentation

The Rushton impeller, or Rushton turbine, is the most commonly used impeller for microbial cultivation. Its blades are flat and set vertically along the agitation shaft, producing a radial flow. It is used with organisms that are relatively resistant to shear stress, such as bacteria, yeasts, and some fungi.

Pitched-blade impellers: For shear-sensitive cells

The blades on pitched-blade impellers are flat and typically oriented at a 45° angle. These impellers produce simultaneous radial and axial flows, providing efficient mass transfer. Pitched-blades are low-shear impellers that gently mix the culture without damaging the cells. They are used for mammalian and insect cell cultures growing in suspension or on microcarriers. Thanks to their proficiency in mixing, pitched-blade impellers are sometimes also used to stir viscous microbial cultures, such as filamentous fungi.

Marine impellers: Even more gentle

The leading face of the blades on a marine impeller can be flat or concave, whereas their back sides are convex. Like pitched-blade impellers, they are used in applications requiring gentle mixing. Marine impellers produce an axial flow, so their mixing efficiency tends to be slightly lower than those of impellers producing both radial and axial flows.

8-blade impeller: Optimized for stem cell culture

Eppendorf developed a 8-blade impeller with 60° pitch to suit the special needs of stem cells. It ensures reduced cell settling and very good mixing already at low agitation speeds to reduce the stress for stem cells and was optimized to support cell aggregate formation.

Packed-bed baskets: Perfect for secreted proteins

In a packed-bed basket impeller, cells are immobilized on or entrapped in a three-dimensional matrix. The basket is comprised of two horizontally positioned, perforated metal plates that extend to the vessel walls. Enclosed between the plates, Fibra-Cel disks or other matrices form a solid bed for cell growth. Cells within the bed are protected from external shear forces. A hollow impeller tube circulates medium, with discharge ports positioned above the basket. As the tube rotates it creates a small negative pressure at the bottom, drawing culture broth into the tube for recirculation. Packed-bed impellers are primarily used for manufacturing high-yields of secreted products from suspension cells or anchorage-dependent cultures in continuous cultivation.

Spin Filters: Perfusion for all cell lines

Spin filters are retention devices designed to keep the cells inside the vessel in perfusion cultivation. Combined for example with low-shear marine impellers they can be used for suspension cells and cells growing on microcarriers. The spin filter consists of a screened cage with very small pore size that keeps cells isolated outside the cage. The cage rotates, attached to the concentric impeller shaft, while inside of it a dip tube continuously withdraws the filtered, cell-free culture broth. For perfusion culture, an addition tube outside the cage provides a steady supply of fresh medium so that the working volume remains at a constant level. This mechanism is ideal for production of secreted proteins: It keeps the harvested medium free of cells, which simplifies downstream purification. Over time, however, the spin filter screen material will tend to clog and require replacement, thus limiting cultivation time.

Lean more about the use of packed-bed bioreactors and spin filters for the cultivation of anchorage-dependent cells.

Special impellers for microcarrier cultures

The cell-lift impeller provides ultra-low shear circulation for microcarrier cultivations. A hollow impeller tube circulates medium. As the tube rotates it creates a small negative pressure at the bottom, drawing culture broth and microcarriers up and delivering them through three discharge ports above and external to the cage. Gases are introduced through a ring sparger, generating bubbles that pass along the impeller in the so-called aeration cage. A mesh lining on the outer membrane of this cage ensures that cells growing on the microcarriers cannot pass through. Gas exchange occurs only at the membrane-media interface so that cells remain in a bubble-free environment and are not subjected to shear stress caused by bursting bubbles. The gas bubbles are then released through two ports at the top of the impeller into a second screened-in cage. Air, supplied by headspace gassing, is directed into this cage to break up foam. Cell-lift impellers are typically used in batch and fed-batch processes with shear-sensitive mammalian cells grown on microcarriers. When a decanting column and media addition tube and harvest tubes are added, they can also be used for perfusion culture.

Interested in more expert advice on bioprocessing topics?

Read more

Read less